Project Description

Overview

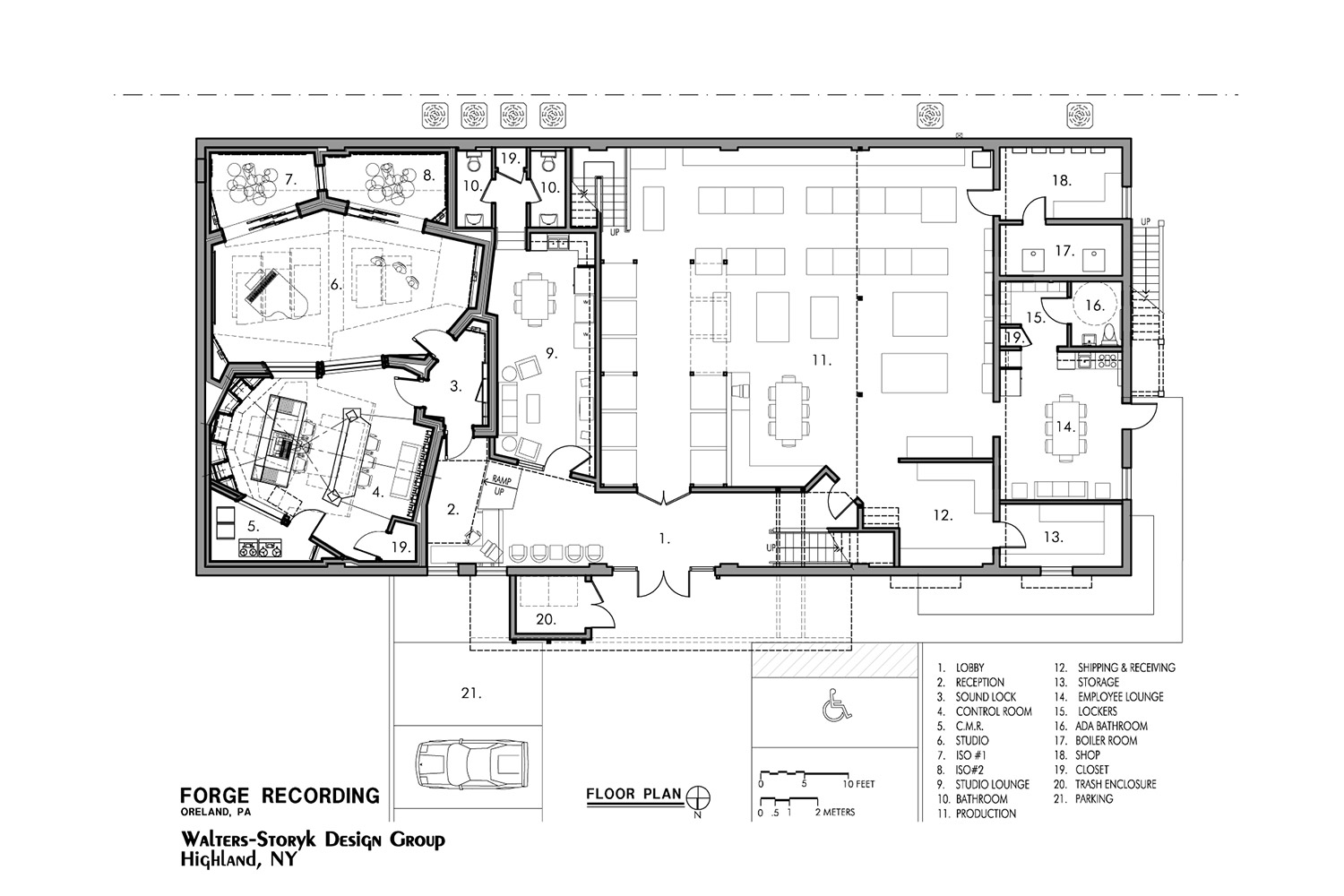

Forge Recording / Replication combines form and function into a new 7000 square foot complex outside of Philadelphia. The studio features a spacious 400 square foot control room and a 900 square foot live room, complete with two isolation booths, which can accommodate a 60-member choir. WSDG’s design also includes 2000 square feet of offices on the second floor while preserving 3000 square feet of open space for production and manufacturing.

The facilities pure acoustical environment, united with aesthetic design, enhances creative and production processes. Forge successfully integrates a state of the art recording and mixing environment with manufacturing and graphics stations. Forge handles every process, from recording to mixing, mastering to duplication.

Forge Recording had already established itself as a successful business in the Valley Forge area outside of Philadelphia, PA, with thousands of recording, mastering and duplication oriented clients. During an era of suffering studio rentals due to the home studio explosion of the early 1990s, Forge built an interesting revenue model that combined income from traditional studio recording, graphics and packaging, and duplication services. The business, which had already been in operation for 25 plus years—purchased by its current owner only two years before—was calibrated for relatively small production runs, and it eventually outgrew its location and required a new, larger, purpose-built site.

An old warehouse was located in Oreland, in the northern suburbs of Philadelphia, within ten miles of its former location. The new facility would have all the elements in place to help Forge expand into new areas such as surround sound and mastering services, while expanding its existing disciplines and retaining its local clients.

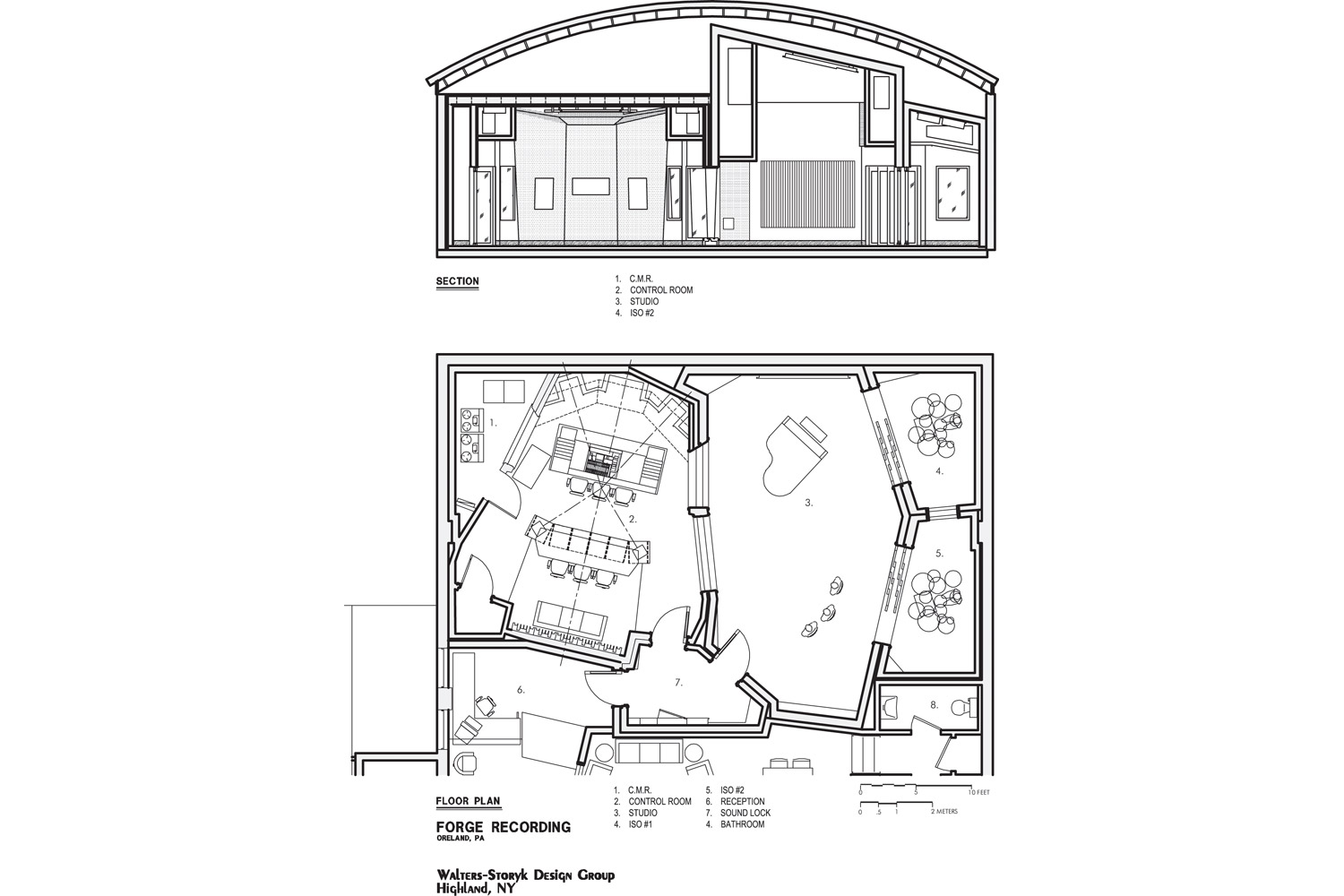

The building had a fantastic ceiling height – 22 feet – a major plus for any acoustic environment. Also, the arched nature of the ceiling, combined with the 2nd floor mezzanine, left WSDG with a column-free environment in which to design. Conceptually, Forge required three distinct, but interrelated, sections to their building, which fed the different lines of business: the recording facility, the duplication operation and the graphics/packaging stations. Interestingly, Forge had evolved into a “one-stop shop”, handling everything from recording, to mastering, to duplication and packaging.

A reasonably sized live room was designed to accommodate up to a 60 person choir, along with a fully surround-capable control room and two generously sized isolation booths adjacent to the live room. Having four acoustic environments that were completely isolated made the recording areas much more efficient and flexible. If needed, mix sessions and tracking sessions could occur simultaneously. Acoustically, the spaces were geared to handle small string ensembles, solo piano, heavy metal bands, and everything in between. The recording areas were a microcosm of the building itself, set up to serve a range of diverse customers and clients.

The 400 foot, acoustically accurate control room is set up to serve groups of music artists, including rock bands. It features a Yamaha DM 2000 digital console, a producer’s desk as well as soffit-mounted Genelec 1038s. The side view into the live area enabled installation of a 5.1 set-up and also allowed advantageous site lines into the two isolation booths. The live room, also adjacent to the isolation booths, is 900 square feet, has generously high ceilings and can accommodate up to a 60-piece choir.

Links

Forge Recording Official Website