Project Description

Overview

Trutone Mastering was started out of a New Jersey basement in the early 1970’s as a part-time business by co-founders Adriana and Carl Rowatti. Back then, the husband and wife team provided services such as vinyl cutting of masters, limited pressing services and some on-location recording. Eventually, the company’s business evolved in the late seventies into in-house design, packaging and high speed cassette manufacturing.

In 2003, the company opened its facility on West 44th street in Manhattan, the original location of Record Plant Studios. In part, this decision was based on the need for the company to be closer to its customers—the producers, artists, record labels and engineers who were literally taking dance, hip hop, R&B and other genres into the next decade. Its clients were also folks who refused to let go of the special warmth and hi-fidelity that is unique to vinyl.

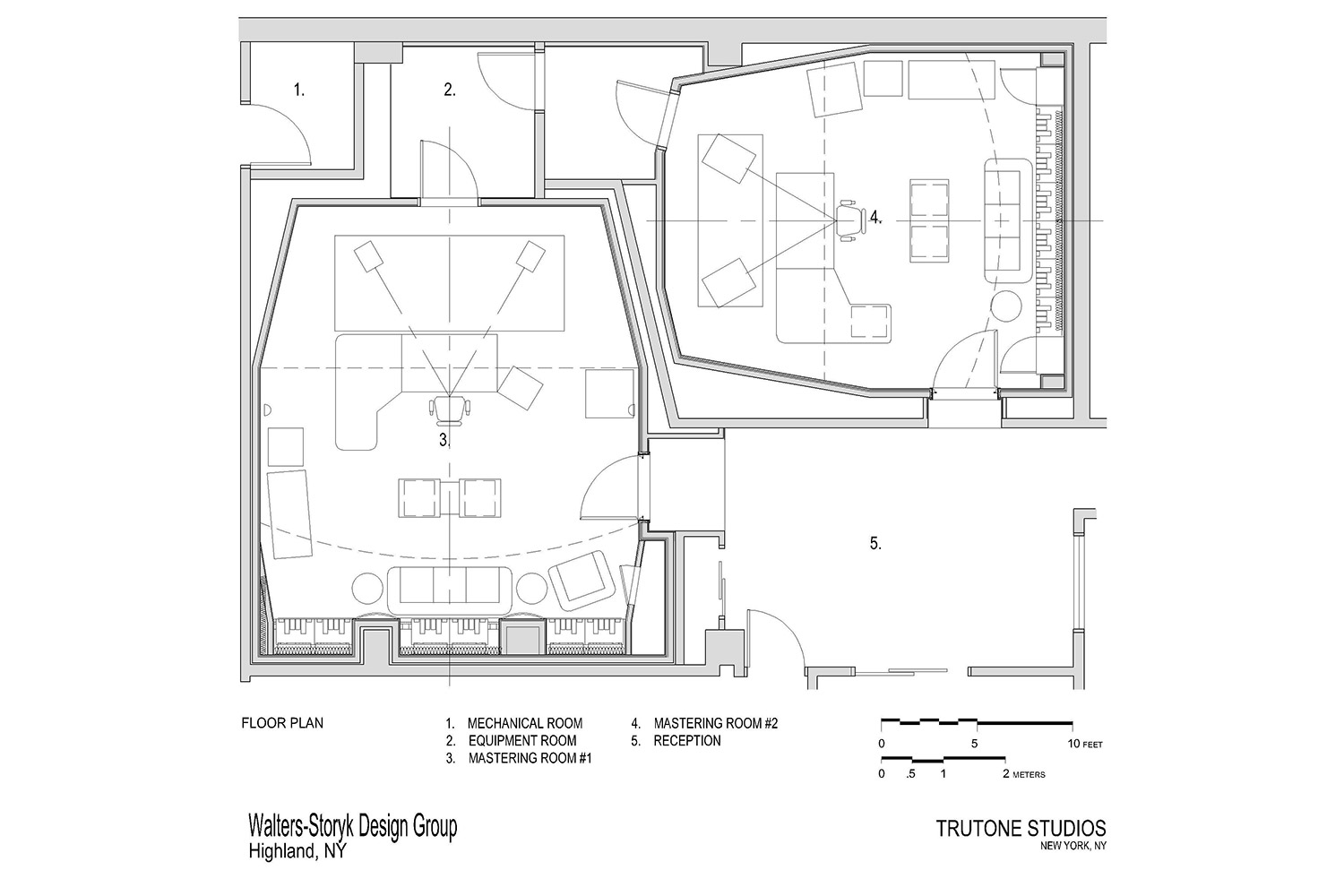

The facility was on the 10th floor of a very good building, and the Rowattis required two fully isolated major mastering rooms, one slightly larger than the other. To some degree, the custom consoles and very specialized equipment would drive the design. As a mastering environment, the isolation requirement was more substantial than that which is typically found in a tracking or mixing environment.

One of the more obvious considerations in the design was the need to create dedicated space for the Neumann lathes. These pieces of machinery were not something that could be slipped into the design at a later point—they were enormous hunks of metal that not only impacted the room reflection, but also conducted considerable sound vibration through the floors. In fact, in the design, Storyk needed to allow for discrete concrete slabs in the floor to maximize isolation.

Aesthetically, the extremely high-end equipment heavily influenced the look and feel of the rooms. The vintage German equipment looks both very industrial and almost colorless—this helped drive the decision to create an environment that was free of distraction. After all, mastering is arguably the stage that requires the most concentration and focus. Since mastering engineers often spend hours by themselves listening and re-listening, the color scheme was very stark and light in some areas to provide as much “visual breathing room” as possible. The net effect is that it looks very airy and easy to work in.

Recently, Trutone has relocated the studio to Rowatti’s suburban 4400 square foot Orangeburg, New York home. The facility features the same technology which earned Carl, Adrianna (his wife and partner) and Trutone Mastering Labss midtown studios recognition as one of New York’s most prestigious mastering complexes. “Last year when Sony BMG Music went looking for a new location for their mastering studios, they offered to buy out our lease,” Carl Rowatti says. “After serious contemplation we decided that their offer was simply too attractive to dismiss.”

“The opportunity to transfer our New York City studio lease to Sony BMG, enabling them to move in and begin mastering with minimal downtime, was testament to the merits of our original WSDG-designed studios,” confides Adrianna Rowatti. The Sony group truly appreciated our facility, it saved them months of construction time and expense”

As soon as the Sony deal was finalized, Carl again consulted with WSDG architect/acoustician John Storyk. “Our engineers and clients were so pleased with the look, sound and functionality of our Midtown studios, that we wanted John to recreate the same ambience for our new home studio. During his first visit to our home in the summer of 2008, John was in full agreement with our assessment of the 1100 square foot site we suggested for the new mastering suite. He also allayed our concerns about maintaining good relations with our suburban neighbors in terms of noise,” Rowatti says. “We also liked his idea of developing a ‘home theater’ look for the new studio to keep it aesthetically appropriate to our home.”

Once plans were approved and finalized, in late 2008, the Rowattis contracted New Jersey-based studio construction pros, Kevin Carroll and Mark Jakubek of Sonic Construction to construct the studio and lounge areas.

Technology

Rowatti depends on the Sonic Studio Pre-mastering System for CD master creation. Outboard equipment includes digital as well as solid state and vacuum tube analog. Gear includes: Weiss BW-102 Digital EQ and Compressors, Solid State Sontec EQ, Prism and NTP Compressors, Vacuum tube gear includes: Pultec and Manley Massive Passive Equalizers as well as the world-renowned Fairchild 670 and Manley Variable Mu Compressors. Analog to digital conversion is achieved utilizing a Prism Sound Dream A/D Converter. Analog disc cutting is accomplished via a meticulously maintained Neumann VMS-70 lathe retrofitted with a Zuma disc computer and Technics quartz-controlled turntable motor. The lathe is equipped with a Neumann SX-74 cutter head driven by a Neumann SAL-74B amplification system. A Neumann SP-77 console has been extensively modified to exceed the demands of today’s high level electronic music. Studio monitors are KEF Reference 4s powered by Bryston and Ramsa amps.

“Thanks to its warmth and sonic vibrancy, demand for vinyl continues to thrive with rock ‘n roll, classic reissues and a growing iPod generation fan base,” Carl Rowatti concludes. “DJ’s have long understood the mystery behind vinyl’s ability to bring a unique emotional experience to today’s club goers. It draws them out of their ear bud cocoons and fully engages them in the hot, exciting communal experience of dance. The sound of vinyl is unmistakable and fortunately for us, irreplaceable.”

Trutone’s success can be attributed to their ability to anticipate and change with the times. They have always been two steps ahead of where the market has gone, always prepared to bring their diverse client base the best services available.

Testimonial

Adrianna Rowatti | Trutone Mastering

Co-founder

“…we decided to move our 25-year-old NJ-based mastering operation to NYC to be more convenient to our clients,” explains “We brought John Storyk and the Walters-Storyk Design Group in to consult on the design and acoustics and were delighted with the results.”