Project Description

Overview

Founded in 1981, TeleProductions, Inc. (TPI) specializes in the production and distribution of television programming for broadcast, cable, satellite and new media audiences around the world. TPI’s television production division develops and produces many of its programs. TPI also co-produces television projects with other companies around the world and also represents a variety of independent producers. TPI’s programming content can be seen on many of the world’s media outlets in Europe, Asia, Africa, the Middle East and the Americas.

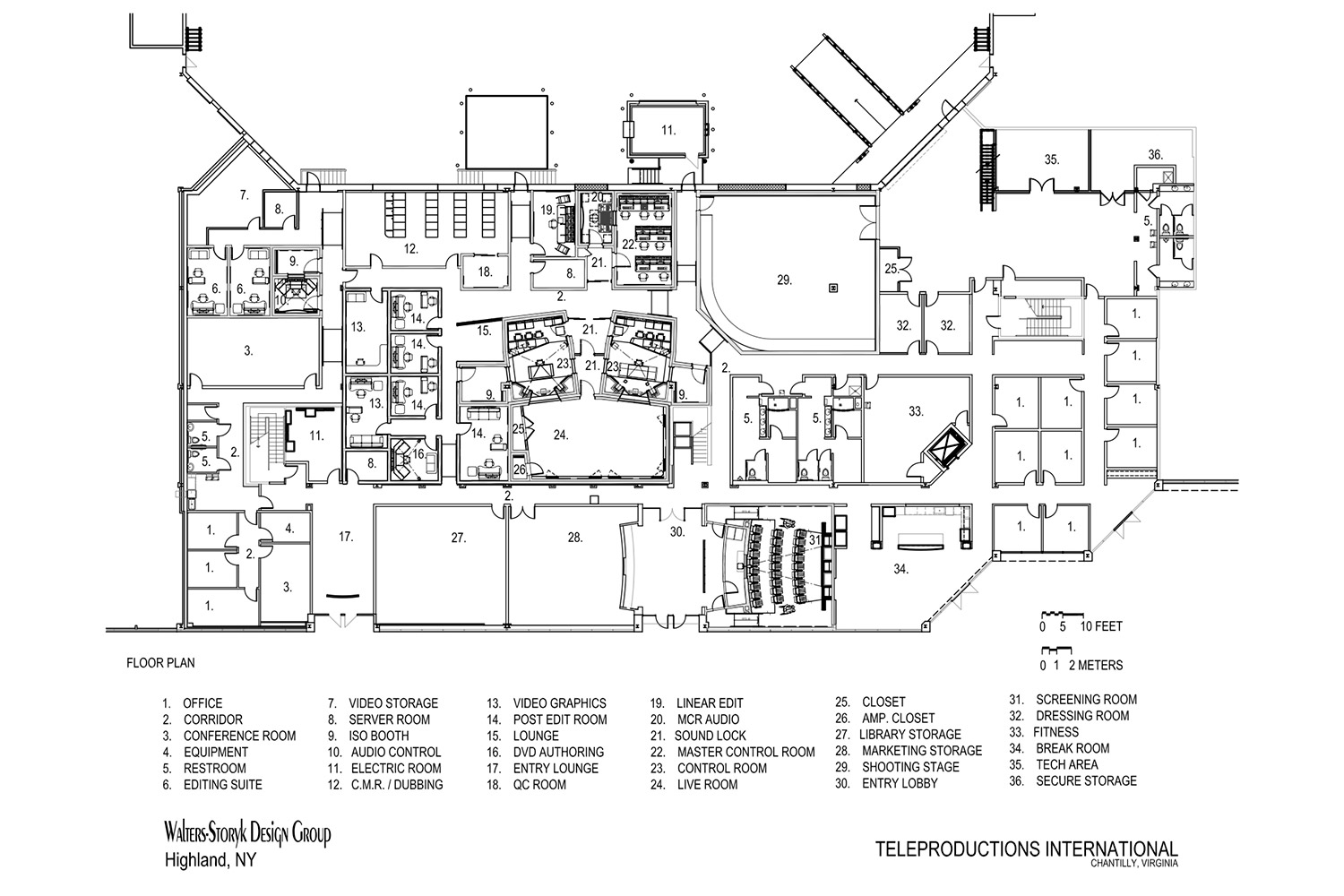

WSDG was called in to assist TPI with a large renovation in its post-production facility at its world-class production headquarters in Chantilly, Virginia. Located in a new building nearby Washington’s Dulles Airport, they had decided to make significant upgrades to the facility that would enable them to branch out into new areas–including being able to record large groups and shoot video on a generously sized stage. This meant they needed a new live room shared between two large control rooms, and a shooting stage with its own dedicated audio control room.

Program

WSDG’s plan included a central machine room (CMR), several edit rooms for post-production work, as well as an entire production suite composed of a small studio (control room and isolation booth) as well as two self-contained edit suites that could be rented out to external clients on an as-needed basis. WSDG also designed a small screening room for their use as well, which included a projector, surround sound system, speaker wall and a large conference room.

A significant obstacle during the design process was the fact the that TPI’s production location was directly within the flight path for Dulles Airport. Therefore, acoustic isolation had to be maintained across the entire frequency spectrum, including within the very low frequency range. Fortunately, there was plenty of ceiling height to accommodate for this requirement, so WSDG was able to implement an isolated acoustic lid, as well as a second non-isolated lid, which was able to double as a mechanical mezzanine so that workers could access duct work and equipment as needed.

Design

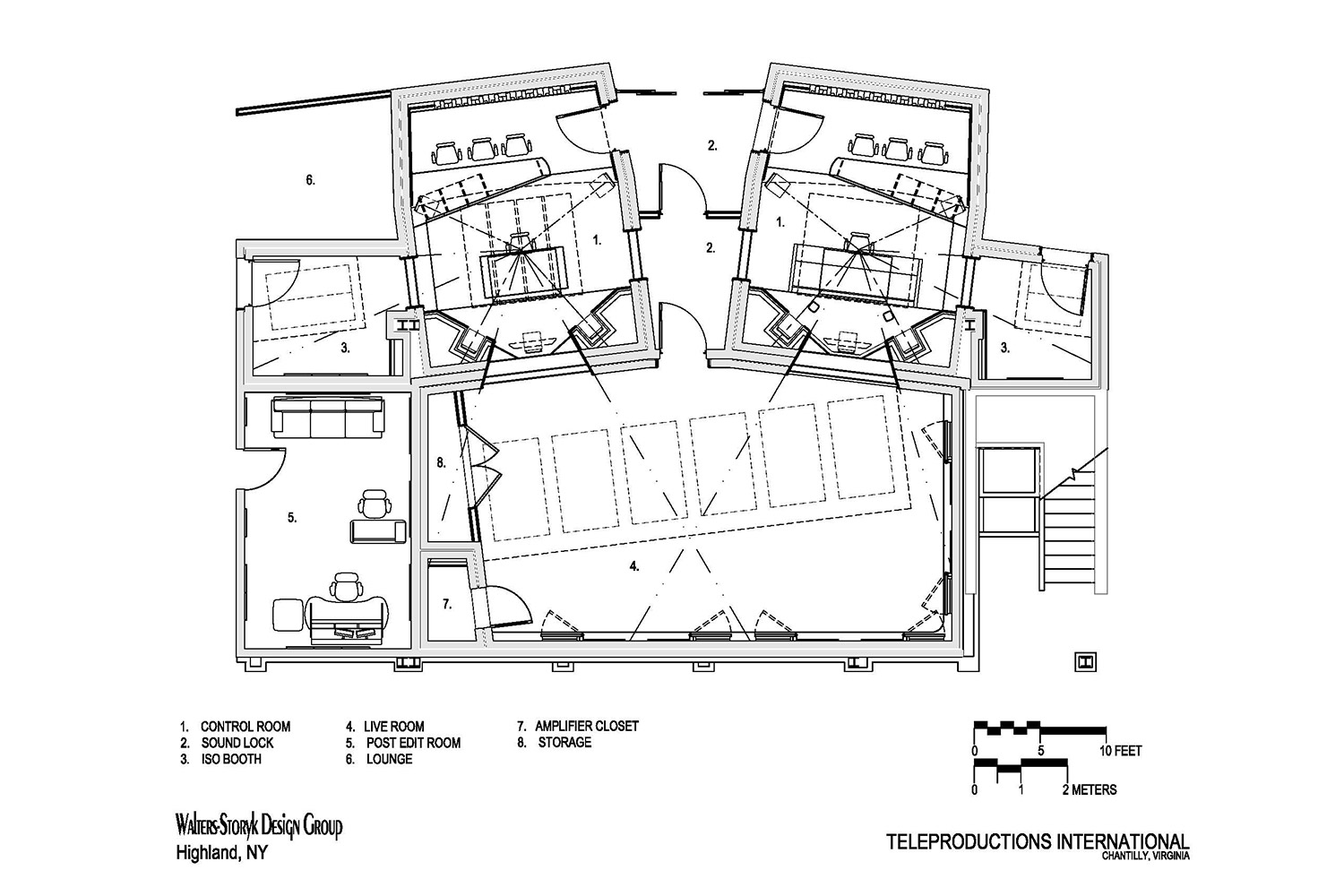

One of the design requirements was to have two large control rooms that shared a single live room, each with its own isolation booth. The operators typically work standing up in these rooms, so WSDG designed an elevated system so that the consoles could be raised to an appropriate operational standing height.

WSDG designed a raised access floor system to ensure easy access to the AV cables that ran through the facility. This solution not only served to help facilitate access, but also helped to keep AV cables away from interference-inducing power cables. Moreover, it made construction easier as empty conduits were not required to inhabit the same space as the mechanical or lighting equipment.

WSDG was responsible for space layout for all acoustic spaces, overall isolation recommendations, design and construction documents for acoustic spaces (including power and conduit accommodation information). WSDG was also responsible for construction administration and worked hand in hand with local architect Sal Poulton of Gileau-Poulton Architects in Woodbridge, VA.